This is our latest post regarding our software ANDI (Automated Nuclear Damage Inspection) and incorporating identification capability with 360 video data.

The 360 camera sector has advanced significantly over the past few years, camera resolution and image quality has improved greatly as well as advancements in software processing to provide multiple different ways of viewing the captured images and video. Cerberus Nuclear has been keeping up to date with latest developments with an aim of using this technology in the nuclear sector.

Cerberus recently developed ANDI (Automated Nuclear Damage Inspection) for Sellafield Ltd. The software automatically identifies key areas of damage from inspection videos and is currently being used by Sellafield to accelerate damage inspection tasks. The software is built into a user-friendly interface and supports the creation of reports and logging of key identified features.

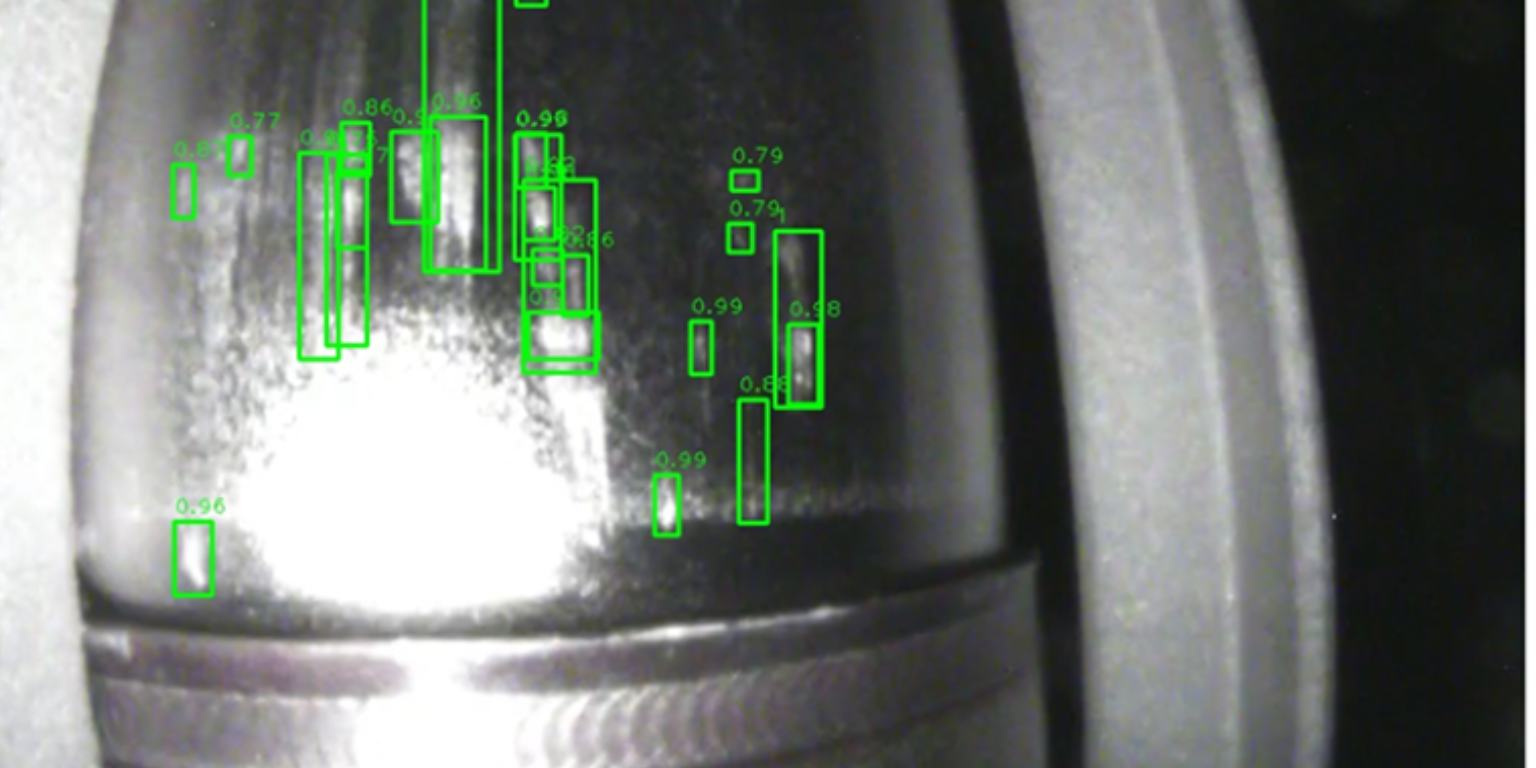

Building upon our knowledge we are currently testing the use of 360 camera and video data with our custom computer vision algorithms, including ANDI. Some key advantages of using 360 data for automated damage inspection is that the orientation of the inspection camera is no longer a factor as images capture the full 360 degrees.

Similar technology is currently being used in autonomous vehicles for object identification and distance determination.

Footage obtained from a Cerberus Nuclear test car.

Our preliminary testing has proved to be very successful and we have overcome some of the challenges inherent in working directly with 360 data sets. The prototype software we have created demonstrates the capability of combining both 360 image technology with our bespoke computer vision algorithms.

Our goal is to continue the development of ANDI so this highly useful and innovative technology can be put to good use solving a wide range of challenges in the nuclear sector and beyond.

Look out for future updates, if you would like to learn more don't hesitate to get in touch at nuclear@cerberusnuclear.com.